INSTALLATION, MAINTENANCE & OPERATION

Installation

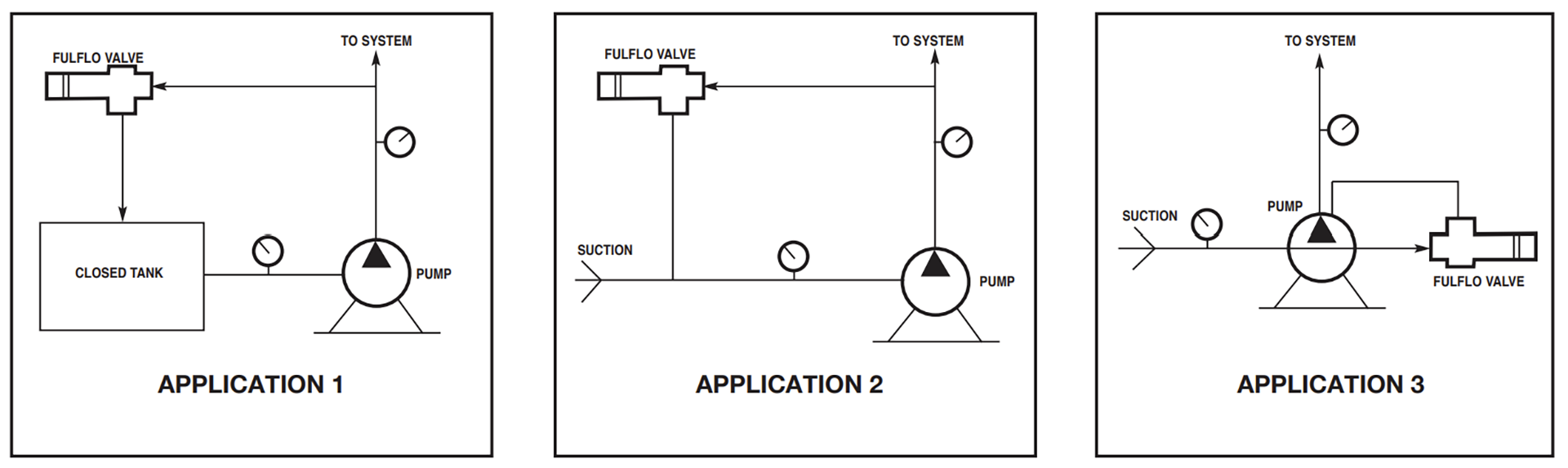

Fulflo valves can be mounted in any position. A tee may be inserted in the pump discharge line to mount the valve. The correct size of the valve should be installed, preferably matching the pump discharge line. Screw the valve into the nipple in the tee, or in the case of the flange style, bolt the valve to the companion flange screwed into the nipple. When the valve is used for frequent bypassing of oil pressure, its outlet should be piped back to the tank. Care must be taken to have the discharge well below the oil level in the tank to prevent air entrainment and erratic operation.

Only if the valve is used as safety or overload relief and operates infrequently may its discharge be piped back into the pump suction line. Frequent or continuous operation under these conditions will cause excessive heating of the oil and possible damage.

Setting Valves

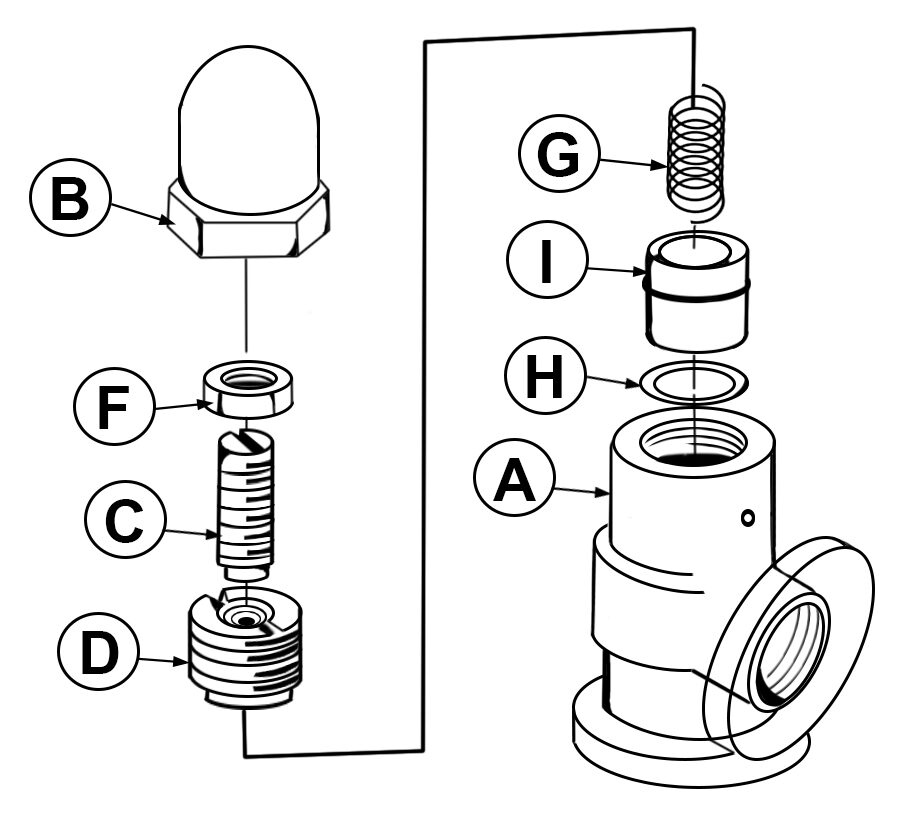

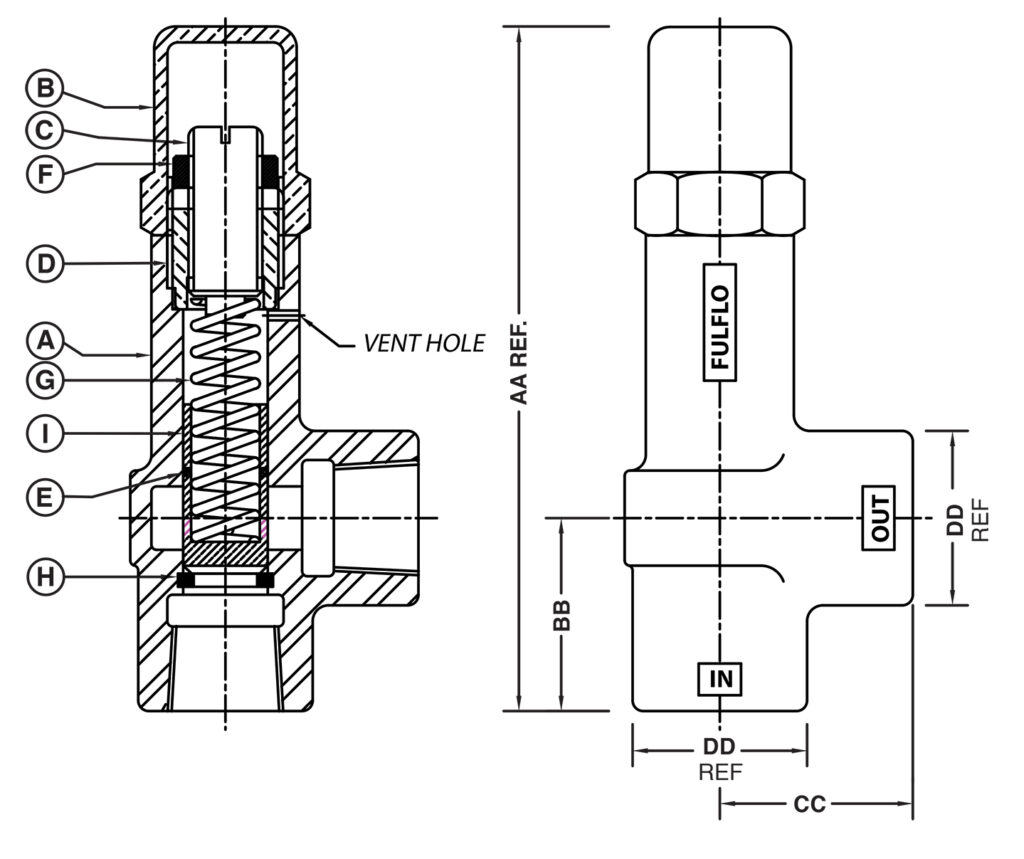

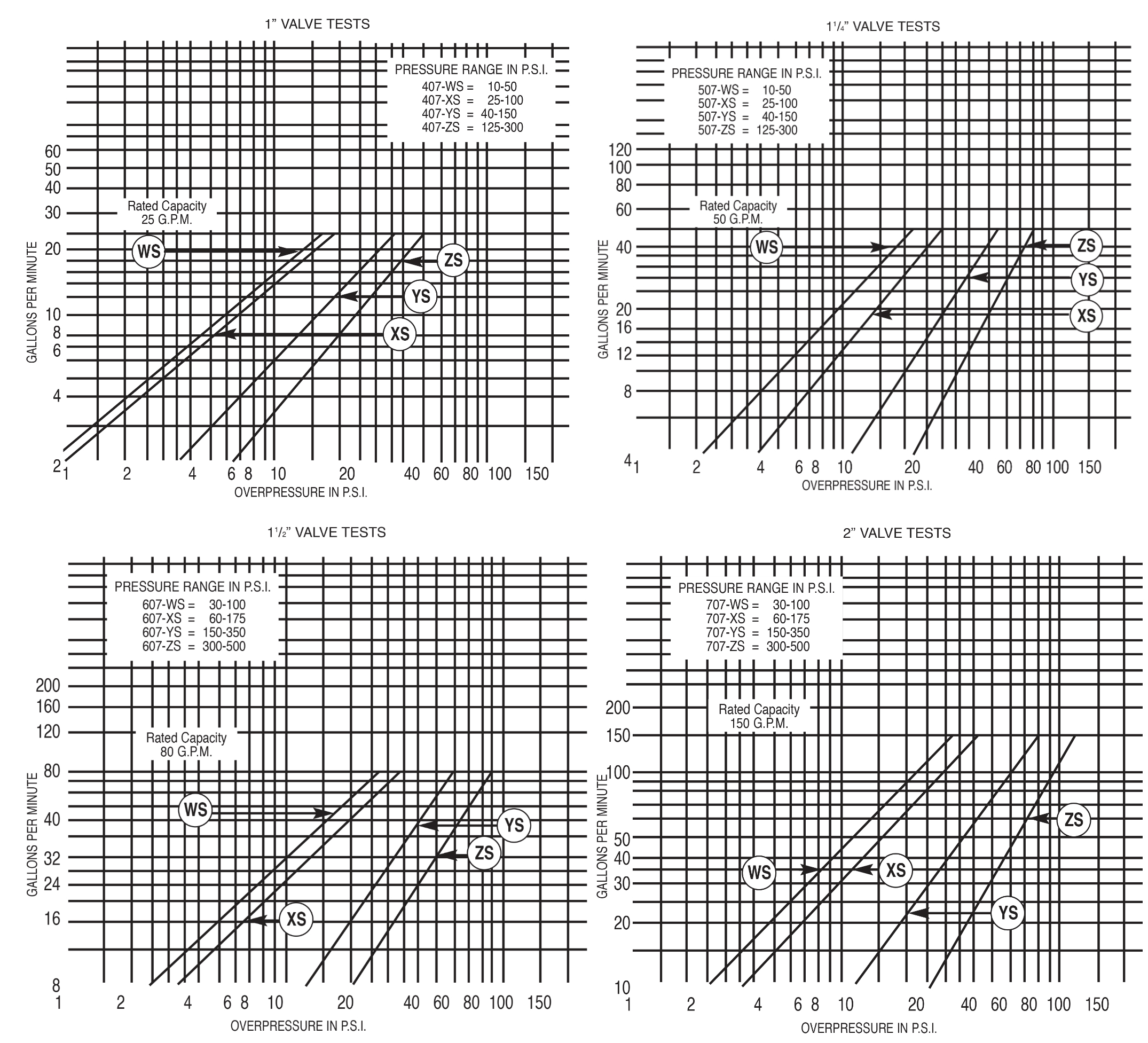

Valves may be set with a hydraulic hand pump for cracking pressure. If a test stand is available, the valve should be connected to the discharge header with the pump bypass open, and the bypass gradually closed until the desired pressure registers on the gauge. Adjust valve adjusting screw until valve slightly bleeds at the set bypass pressure and lock adjusting screw.

Fulflo valves are not designed to be positive shut-off and will pass a minimal amount of leakage before the set pressure. If a valve is required to bypass a given amount of fluid at a given pressure, a test stand having a flow meter in the pump discharge line must be available. With a valve adjusted for cracking pressure as above, continue closing the bypass until the required flow registers on the flow meter and observe pressure. Readjust pressure, if necessary, to obtain desired pressure at desired flow.

Maintenance & Operation

Fulflo valves provide reliable “chatter-free” operations when the system is free of abrasives and foreign matter. Continuous filtration of the liquid used is strongly recommended.