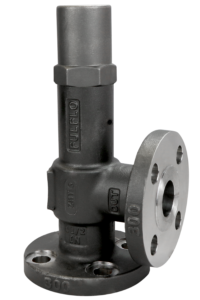

OV-Series Standard with Flange Connections

Models

OVBF: Brass

OVJF: Cast Iron

OVSF: Cast Steel

OVSSF: Stainless Steel

OVJF‐SP: Cast Iron with Steel Parts

- API 520 & 614 Approved

- Chatter-free operation

- Mount in any position

- Suitable for continuous duty

Size Range: 1″ – 2″

Pressures: 10 – 500 psi

Flow Rate: Up to 150 gpm

INSTALLATION, MAINTENANCE & OPERATION

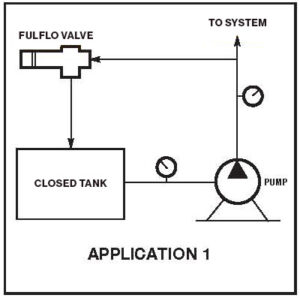

Installation

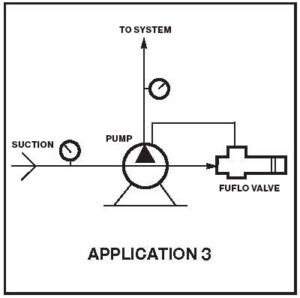

Fulflo valves can be mounted in any position. A tee may be inserted in the pump discharge line to mount the valve. The correct size of the valve should be installed, preferably matching the pump discharge line. Screw the valve into the nipple in the tee, or in the case of the flange style, bolt the valve to the companion flange screwed into the nipple. When the valve is used for frequent bypassing of oil pressure, its outlet should be piped back to the tank. Care must be taken to have the discharge well below the oil level in the tank to prevent air entrainment and erratic operation.

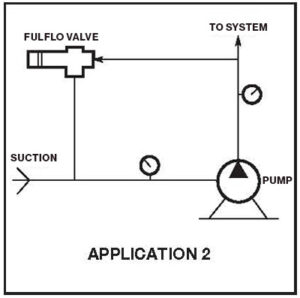

Only if the valve is used as safety or overload relief and operates infrequently may its discharge be piped back into the pump suction line. Frequent or continuous operation under these conditions will cause excessive heating of the oil and possible damage.

Setting Valves

Valves may be set with a hydraulic hand pump for cracking pressure. If a test stand is available, the valve should be connected to the discharge header with the pump bypass open, and the bypass gradually closed until the desired pressure registers on the gauge. Adjust valve adjusting screw until valve slightly bleeds at the set bypass pressure and lock adjusting screw.

Fulflo valves are not designed to be positive shut-off and will pass a minimal amount of leakage before the set pressure. If a valve is required to bypass a given amount of fluid at a given pressure, a test stand having a flow meter in the pump discharge line must be available. With a valve adjusted for cracking pressure as above, continue closing the bypass until the required flow registers on the flow meter and observe pressure. Readjust pressure, if necessary, to obtain desired pressure at desired flow.

Maintenance & Operation

Fulflo valves provide reliable “chatter-free” operations when the system is free of abrasives and foreign matter. Continuous filtration of the liquid used is strongly recommended.

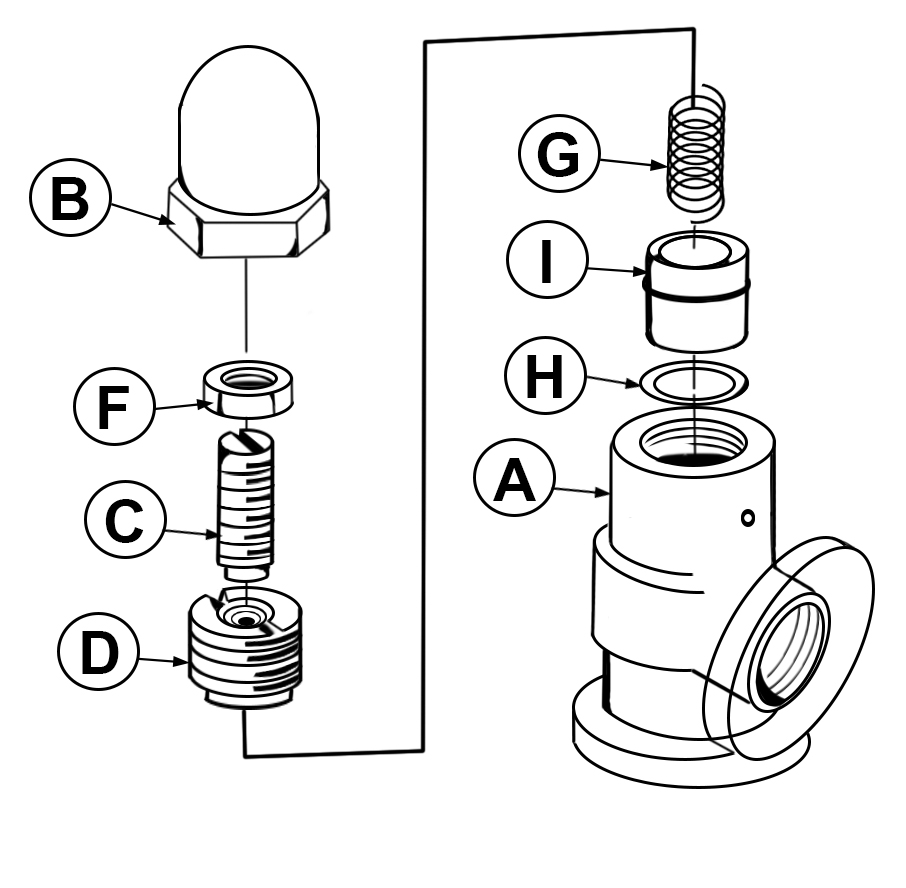

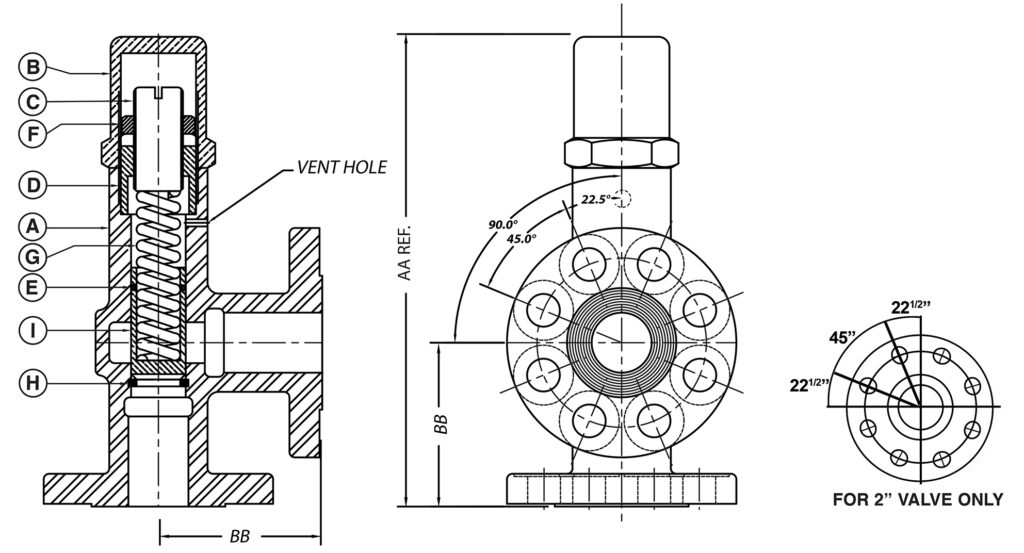

TYPICAL DISASSEMBLY OF STANDARD TYPE VALVE

To dismantle valve for inspection or cleaning:

- Remove cap “B”

- Remove lock nut “F”

- Remove adjusting screw “C”

- Remove retainer “D”

- Remove spring “G”

- Remove piston “I”

- Remove stop ring “H” (Not Recommended-special tooling is required to install new stop ring)

Inspect valve bore and piston for wear and scoring. Replace broken or damaged parts. Clean all parts thoroughly and re-assemble by reversing the above procedure.

ASSEMBLY NUMBER IDENTIFICATION CHART

| Symbol Number | Designation | Code | Description |

|---|---|---|---|

| 1 | Style | None | Standard Model |

| 2 | Series | OV | |

| 3 | Material | J B S SS |

Cast Iron Brass Steel Stainless Steel (300 Series Stainless) |

| 4 | Connections | None F |

Screw Connections Flange Connections 300# Flange Class Standard (250# Flange Class – Cast Iron standard) |

| 5 | Size | -3 -4 -5 -6 -7 -8 |

1/2” 3/4” 1” 11/4” 11/2” 2” |

| 6, 7, 8 | ASA Flange Rating |

None -150 -600 |

300# Flange Standard (no designation required) |

| 9 | Flange Style 150# & 600# Only |

A B C D |

Raised Face, Staggered Bolt Centers Smooth Face, Staggered Bolt Centers Raised Face, Bolts on Valve Centerline Smooth Face, Bolts on Valve Centerline |

| 10 | O-Ring Material |

R RV RS RA EPR RN |

Buna (standard) Viton Silicone Aflas Ethylene Propylene Neoprene |

| 11 | Options | SP | Steel Parts (used on Cast Iron valves only) |

| 12 | Piston Material |

/HS /SS /3SS |

Hardened Steel 416 Stainless Steel 303 Stainless Steel (For Stainless valves only) |

| 13 | Spring

|

/WS /XS /YS /ZS |

See Chart Below for Pressure Ranges |

| 14 | Setting | Desired Set Pressure |

Examples

OVJF-5RVSP/HS/WS |

|||||||

OV |

J |

F |

-5 |

RV |

SP |

/HS |

/WS |

OVJF-5R/HS/WS |

||||||

OV |

J |

F |

-5 |

R |

/HS |

/WS |

OVJF-5-150AR/HS/WS |

||||||||||

OV |

J |

F |

-5 |

-150 |

A |

R |

/HS |

/WS |

||

Standard Pressure Range Chart

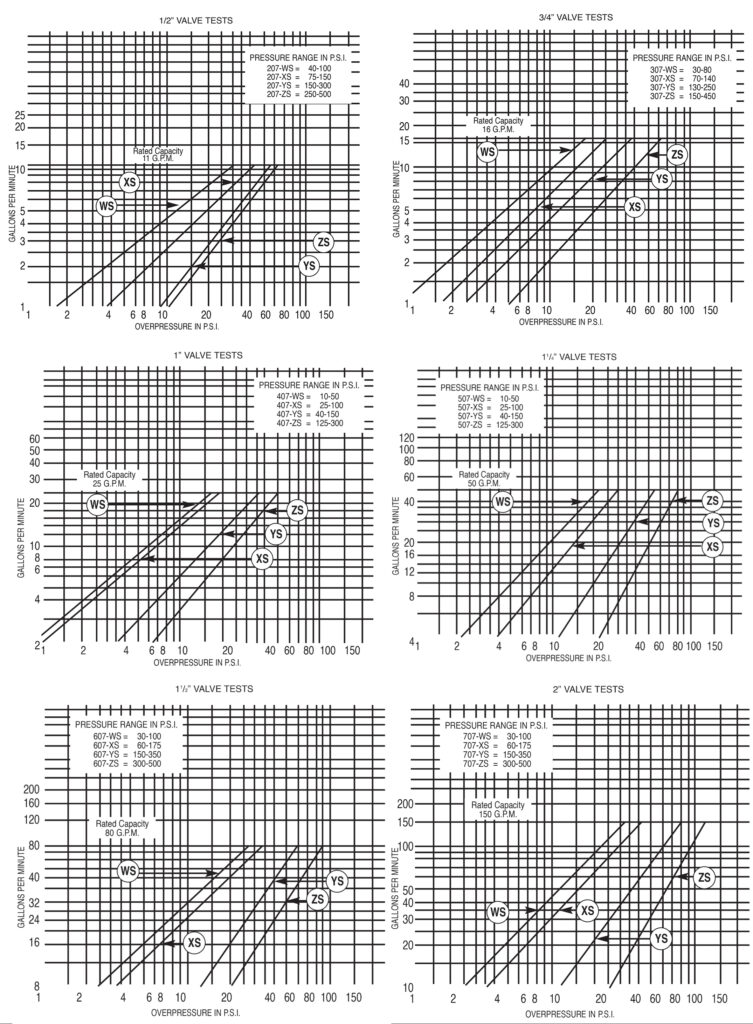

Spring Pressure & Identification No. |

|||||||||

| GREEN-WS | YELLOW-XS | WHITE-YS | BLUE-ZS | ||||||

| Valve Pipe Size | Valve Flange Size | Low | High | Low | High | Low | High | Low | High |

| 1/2″ | 40 | 100 | 75 | 150 | 150 | 300 | 250 | 500 | |

| 3/4″ | 30 | 80 | 70 | 140 | 130 | 250 | 150 | 450 | |

| 1″ | 1″ | 10 | 50 | 25 | 100 | 40 | 150 | 125 | 300 |

| 11/4″ | 11/4″ | 10 | 50 | 25 | 100 | 40 | 150 | 125 | 300 |

| 11/2″ | 11/2″ | 30 | 100 | 60 | 175 | 150 | 350 | 300 | 500 |

| 2″ | 2″ | 30 | 100 | 60 | 175 | 150 | 350 | 300 | 500 |

DIMENSIONS & PARTS

Parts List

Valve Size |

||||||||||||

| Sym. | Name | Model | 1” | 11/4“ | 11/2” | 2” | ||||||

| A | Body | OVJF, OVJF-SP OVBF OVSF OVSSF |

500-F39 500-BF39 500-SF39 500-SSF39 |

600-F25 600-BF25 600-SF25 600-SSF25 |

700-F27 700-BF27 700-SF27 700-SSF27 |

800-F30 800-BF30 800-SF30 800-SSF30 |

||||||

| B | Cap | OVJF, OVJF-SP OVBF OVSF OVSSF |

501 501-B 501-S 501-SS |

601 601-B 601-S 601-SS |

701 701-B 701-S 701-SS |

801 801-B 801-S 801-SS |

||||||

| C | Adjusting Screw | OVJF, OVBF OVSF, OVJF-SP OVSSF |

502-B 502-S 502-SS |

602-B 602-S 602-SS |

702-B 702-S 702-SS |

802-B 802-S 802-SS |

||||||

| D | Retainer | OVJF, OVBF OVSF, OVJF-SP OVSSF |

503-B 503-S 503-SS |

603-B 603-S 603-SS |

703-B 703-S 703-SS |

803-B 803-S 803-SS |

||||||

| E | Piston O-Ring+ | All Models | 204-* | 7073-* | 7069-* | 7064-* | ||||||

| F | Lock Nut | OVJF, OVJF-SP, OVSF, OVBF OVSSF |

505-S 505-SS |

605-S 605-SS |

705-S 705-SS |

805-S 805-SS |

||||||

| G | Spring+ | All Models | 407-** | 507-** | 607-** | 707-** | ||||||

| H | Stop Ring | OVJF, OVBF OVJF-SP, OVSF OVSSF |

508-B 508-S 508-SS |

608-B 608-S 608-SS |

708-B 708-S 708-SS |

808-B 808-S 808-SS |

||||||

| I | Piston+ | Hardened Steel 416 Stainless Steel 303 Stainless Steel |

506-32 506-A32 506-SS32 |

606-32 606-A32 606-SS32 |

706-25 706-A25 706-SS25 |

806-23 806-A23 806-SS23 |

||||||